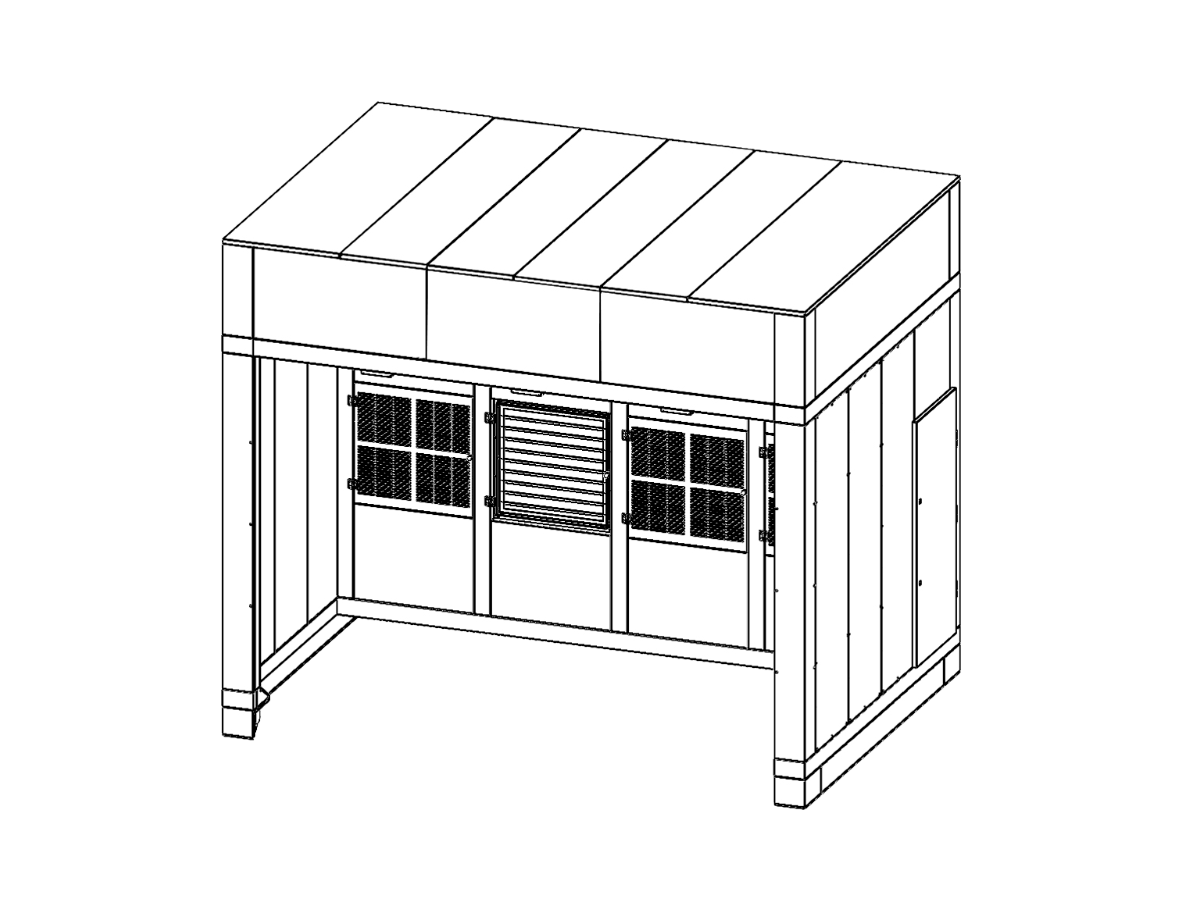

Cleanroom door specifications and accessories tailor-made to your needs

Cleanrooms are critical in various industries such as pharmaceuticals, biotechnology, and electronics. They are designed to maintain a controlled environment with low levels of airborne particles, bacteria, and other contaminants….