Picking the right storage units for a clean room is undoubtedly one of the key considerations of clean room interior design. Since the area of the clean room affects the cost of both initial installation and maintenance, space should be maximized and used efficiently. This is why practical clean room storage cabinets may come very handy. Depending on the industry, storage needs may vary, but they always need to be functional, space-efficient and impeccably hygienic.

Clean room cabinets may store tools and equipment, biological samples and other substances, clean room garments, gowns, and shoes, cleaning supplies and other industry-specific items.

Role of storage in clean rooms

When clean room design is discussed, storage and transport of materials generally stay away from the limelight, but both are essential steps of the manufacturing process. Especially in industries where highly sensitive parts and devices are used, it is critical that they maintain impeccable hygiene throughout transportation and storage.

Remaining in one place undisturbed does not necessarily mean no risk of contamination. Objects may get contaminated while being stored for a longer period. What’s more, sensitive parts and devices may be subject to being damaged potentially by humidity or oxygen.

For this reason, application of special clean room storage systems is critical to be able to provide optimal and hygienic conditions for germ-free storage. Garments, for instance, are often stored in clean room storage cabinets since maintaining their cleanliness integrity is key.

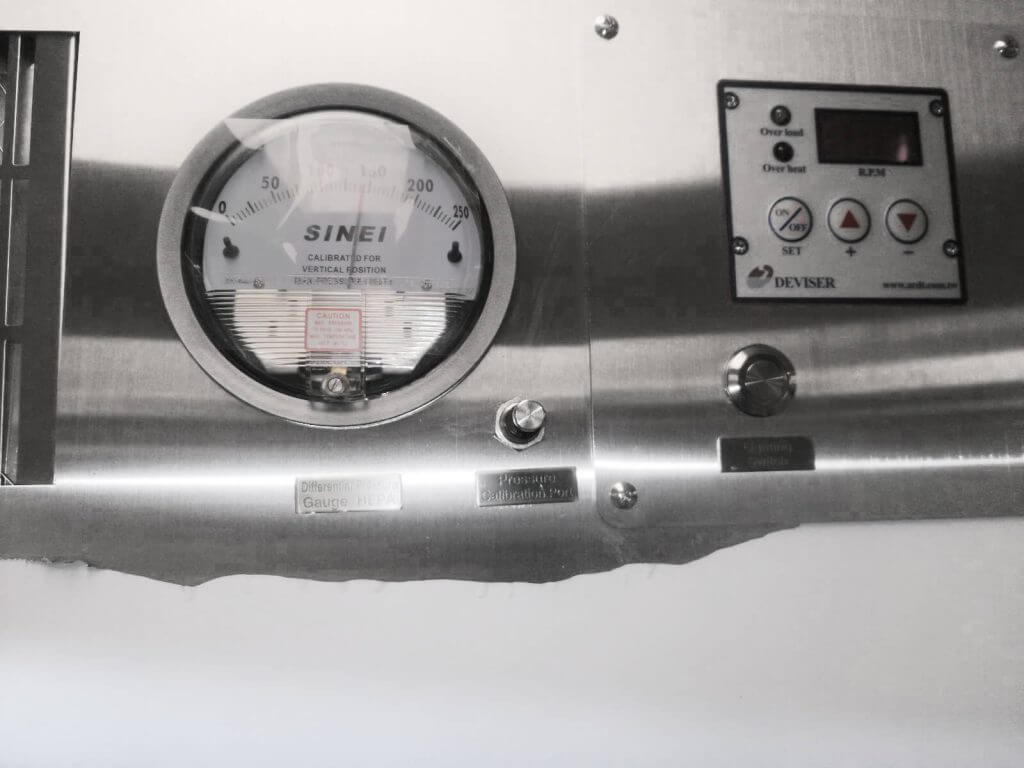

Pressure gauge and control panel of a clean room storage cabinet

Key aspects to consider when choosing the right clean room storage solution

Similarly to pass boxes, clean room storage cabinets can be equipped with their own ventilation or can be connected to the clean room’s air handling system. Active models are furnished with fan filter units - or FFUs in short - for air supply, mounted above the HEPA filter. A continuous incoming air flow ensures that particulates cannot enter the storage unit.

To preserve the stored object’s hygiene, storage solutions can control for various parameters such as humidity, temperature or positive pressure. Depending on the exact model, clean room storage cabinets provide 5-25 air exchanges per hour. Also, some applications may require not only clean, but also sterile cabinets.

Active / Semi-active clean room storage cabinets

Active clean room storage cabinets are equipped with a pre-filter and a 570*570*50 w aluminum frame HEPA filter that prevents particulates above 0.3 um from entering at a 99.99% efficiency. Active models are equipped with their own fan filter units for ventilation, therefore they do not need to be connected to the clean room’s air handling system.

Semi-active clean room storage cabinets are furnished with their own filtration, but do not contain a built-in air supply. For this reason, they must be connected to an already existing air handling system.

Clean vs. sterile storage units

If a sterile environment is required to store specific items, it can be achieved by UV sterilization with germicidal lamps. In one of our previous articles, we have already touched upon the differences between clean rooms and sterile rooms and identified the most common practices used to create sterile environments.

In case of sterile storage, sterility is achieved with germicidal lamps, however, it is usually combined with a clean environment, meaning that sterile cabinets also filter for particulate contamination and maintain a positive pressure enclosure.

Shelving, clothes racks & other accessories

To maximize space utilization, it is practical to opt for shelving with versatile configuration and adjustable accessories so that objects and equipment can be stored in various ways. Placement and the number of clothes racks needed are also key considerations. Before procurement, it is advised to take into account the capacity needed. Make sure you can store as many garments as you may need, but also do not have a lot of unused capacity.

Introducing KleanLabs clean room storage cabinets

KleanLabs manufactures self-designed clean room storage units for various industries both in standard and custom sizes. Models with custom dimensions meet the needs of highly specific clean room workflows perfectly while standard models are incredibly versatile and perfect for most clean room applications.

KleanLabs clean room cabinets are all made of extremely durable stainless or powder coated steel. Both are extremely resistant to chemicals and easy to clean in order to help maintain impeccable hygiene in clean rooms. KleanLabs clean room storage units are available with full-size glass doors and two-sided access on request.

Storage unit in a clean room changing room

Active KleanLabs clean room garment & shoes storage cabinets

Active KleanLabs clean room garment & shoes storage cabinets have been designed specifically with clean room gowning in mind. Clean room garments may accumulate particulate contamination during storage between laundry washes, which may have an impact on general quality issues in production. Therefore, preventing contamination during storage is key. Our active clean room garment & shoes storage units are equipped with their own ventilation. Air is supplied by a fan filter unit - FFU in short. Shelving in this model is entirely adjustable.

Active KleanLabs clean room garment & shoes storage cabinets

Semi-active KleanLabs clean room garment storage cabinets

The semi-active KleanLabs clean room garment storage cabinet features acrylic or glass door panels for easy visibility of stored items. This model is suitable for storing 6-8 clean room garments.

While the semi-active KleanLabs clean room garment storage units are equipped with adequate particulate filtration, to ensure a continuous air supply, they must be connected to the already existing air handling system of the clean room.

Semi-active KleanLabs clean room shoes storage cabinets

Semi-active KleanLabs clean room shoes storage cabinets

Semi-active KleanLabs clean room shoes storage cabinets have been designed to store several pairs of shoes - 18 to be exact. Front doors are not see-through, but made of powder coated or stainless steel. Since this model is also semi-active, it must be connected to the clean room’s air handling system, as well.