Cleanliness is one of the greatest values of today’s world. The pandemic situation emphasized the importance of disinfection and control over vulnerable materials. Therefore, it is high time to examine safety equipment and review higiene protocols of the most sensitive places of work.

Containment suits, laboratories and cleanrooms require an extreme level of filtration and strict access control management, especially when it comes to personnel entering and leaving precious workplaces.

The latter has usually been solved by:

the application of interlocking door systems, or, more perceptibly, airlocks or mantraps at most areas. This system is really effective, and, when operated in the right way, can eliminate malfunctions due to human errors too.

What is an interlocking door system?

Cleanrooms and other areas with special hygienic requirements usually demand two kinds of protection:

- On one hand, the security system needs to protect the cleanliness and pressure balance of the room itself.

- On the other hand, the system has to provide control over the access to the area, preventing it from accidental or malicious entries. Interlocking door systems are capable of serving both needs.

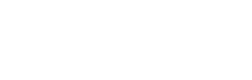

The concept of mantrap is relatively simple:

The system stands of two doors that are electronically connected to each other. One door cannot be opened until the other one hasn't been closed. For a given period of time, the two doors create a booth that can be used for various purposes.

It can be either an airlock, a simple dressing room, a security gate or all of them - depending on the health and safety requirements of the given property.

Mantraps can create an airlock, function as a dresser or a security gate, as well

Why not use a simple double door like the ones in a supermarket?

This system is capable of providing an air-tight separation for the room it protects. Being automatized, the system can prevent any error due to the human factor: doors cannot be left open, and the locked period gives the guards or personel the opportunity to block any unwanted or unauthorized entries.

Detection and identification systems: bringing safety to the next level

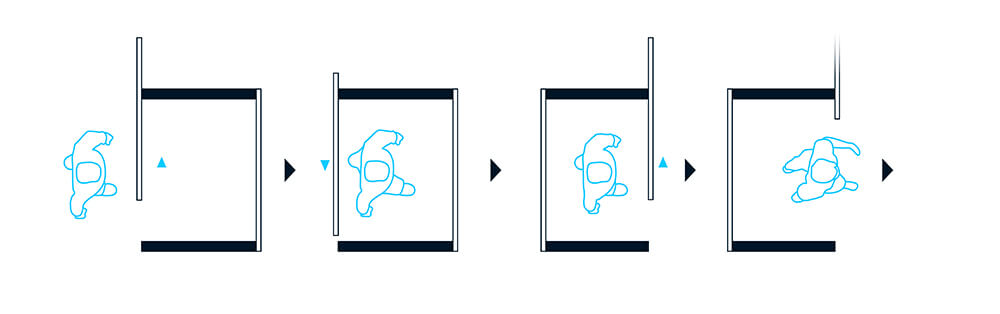

While plenty of mistakes are possible to avoid even by using the simplest automatized interlocking door system, cleanrooms often require a more sophisticated protection, especially when it comes to security. Luckily, the most modern mantraps can be equipped with a range of tools that can help prevent malicious entries.

Interlocking door systems can prevent “piggybacking” that is allowing another person to sneak in behind someone authorized

Security cameras are now usual accessories of these airlocks, however, there is still a wide range of detection and identification systems that can bring the safety of mantraps to the next level:

- Weight and motion detection: Sensors can recognize when, for example, more than one person entered the booth, therefore, they can automatically prevent the second door from opening. Weight, motion or metal detectors can filter out unusual or suspicious entries, block the access and warn the staff in charge.

- Manual controls: The automatic system can also be mixed with human control. For instance it is possible to set the second door to open only when the person in the transit area has been cleared access and the entry is permitted by an operator or a security guard.

- Identification methods: Pin code systems and entry cards can also be used to filter personnel that try to enter. In case further protection is needed, even biometric readers can be used, these can include retina or fingerprint detection, or even voice sampling.

These double and single door systems can also come with functionalities such as customizable delay between the openings (adjustable length of transit periods), emergency opening systems, security panels and windows. Therefore, an interlocking door system is not only the guard of hygiene, but also an advanced security solution.

What is the difference between soft and hard interlocking systems?

Safety first! - goes the old saying.

However, cost efficiency has also a certain importance, especially when it comes to rather exorbitant projects. Of course, not all laboratory entrances have to be equipped with high-level security systems. Sometimes a simple, reliable, and easy-to-use solution is the wiser choice.

In terms of technologies, interlocking door systems fall into two categories:

There are soft interlocks and hard interlocks.

It is important to highlight that they are not superior to one-another. While certain projects require advanced protection, others may need an efficient yet more affordable solution. Below there are the main characteristics of these two groups.

Soft interlocks

Soft interlocks are typically used in the field of education or by basic level scientific or engineering projects. These systems are characterized by their very simple design and therefore lover protection against breaches of protocol. However, these are more affordable, and efficient enough to create a clean environment for work.

Soft interlocks may not even be fully automatic:

In many cases, doors are merely equipped with a window or a vision panel. This allows the entering person to see whether the second door is open. There is often a visual indicator, e.g. a red and green light or a Do not enter sign that helps to indicate if it is allowed to enter to the transit area, or one needs to wait for the next door to close. An audible signal may also be added: a siren or alarm may go off when any of the doors open, and will not stop until that is closed properly.

The operation of these doors require attention and discipline, since there may not be any automatisms to prevent the opening of one door while the other is open as well. However, despite the shortcomings in security, they are perhaps the best available solutions for a wide range of environments.

Hard interlocks

In contrast to soft interlocks, hard interlocks feature an additional locking system that provides an extra level of security:

Both doors are equipped with a position switch and an electronically controlled locking device. This system minimizes the chance for the two doors to be opened at the same time. In cleanroom environments they usually work with an electromagnet, therefore named “mag-locks”.

Hard interlocks are fully automatic, therefore when one door opens, the other gets locked. In order to facilitate an easy operation, they can also utilize a similar alarm and indication signal to soft interlocks.

Cleanroom specific interlocking door system design

According to ISO 14644 standard, cleanrooms are required to be equipped with either a soft or a hard interlocking system. This requirement challenges both engineers and manufacturers, especially when it comes to the modernisation of existing or modular systems. Many of these are not equipped with interlocks, which means that the system has to be added later in order to meet the standard.

There are only a few manufacturers that are able to produce site-specific interlock solutions. KleenLabs is one of them. Their products are not only perfect for facilitating existing cleanrooms to the standards. They can also fulfill the need of special application of interlocking, for example in the area of manufacturing.

Designing interlocking system is a complicated process, as there are several factor to pay attention to:

- Budget.

While soft interlocks are more cost-efficient, they may have shortcomings even in terms of cleanliness. - Field requirements.

Size, pressure, temperature, frequency of usage also must be calculated with. Cleanrooms are not the only areas that require interlocking protection. For instance in manufacturing the doors are often used to protect machinery that is in operation. This type of utilization has many different challenges in comparison with cleanrooms. - Health and safety.

Soft interlocks may fall short in effectiveness, however, hard interlocks may also have some safety issues when it comes to an escape plan, for instance.

Finding the right solution is always the result of careful calculation and planning. With years of experience, KleanLabs is ready for this challenge. Being the supplier of several various projects, we have built a secure knowledge base that helps product design and allows our solutions to be adjusted to even the most specific needs. Whether it is a cleanroom environment or a special client area to be protected, our interlocking door systems can provide a range of possibilities to create a safe and secure place to work.