Hutoepito, the parent company of KleanLabs applied for a grant to fund research, development, and innovation activities.

The HUF 197.85 million non-refundable grant for "Upcycling of closed-cell rigid polyurethane foams" was approved by the Ministry of Finance. The project is scheduled to be completed till 31 January 2025. As we use large quantities of polyurethane-based foams to manufacture industrial cold room walls, this research is of great importance to us.

Brief overview of the research grant

Introducing the problem

Based on our own experience, the processing technology of polyurethane (PUR) foams results in a lot of excesswaste, close to 500 m3 per year in our plant only. A significant part of the waste accumulation is due to scrap material left over from the production of polyurethane blocks.

What is our goal?

Our aim is to develop a new technology to upcycle a.k.a. re-use closed-cell, rigid, cross-linked polyurethane foam materials to reduce or eliminate production waste produced by our company or other market players in Hungary or even in the Central European region.

The solution

Based on our preliminary research, various urethane prepolymers prove to be primising binders. Crosslinking of these materials at room temperature can be achieved by adding water and a small amount of catalyst.

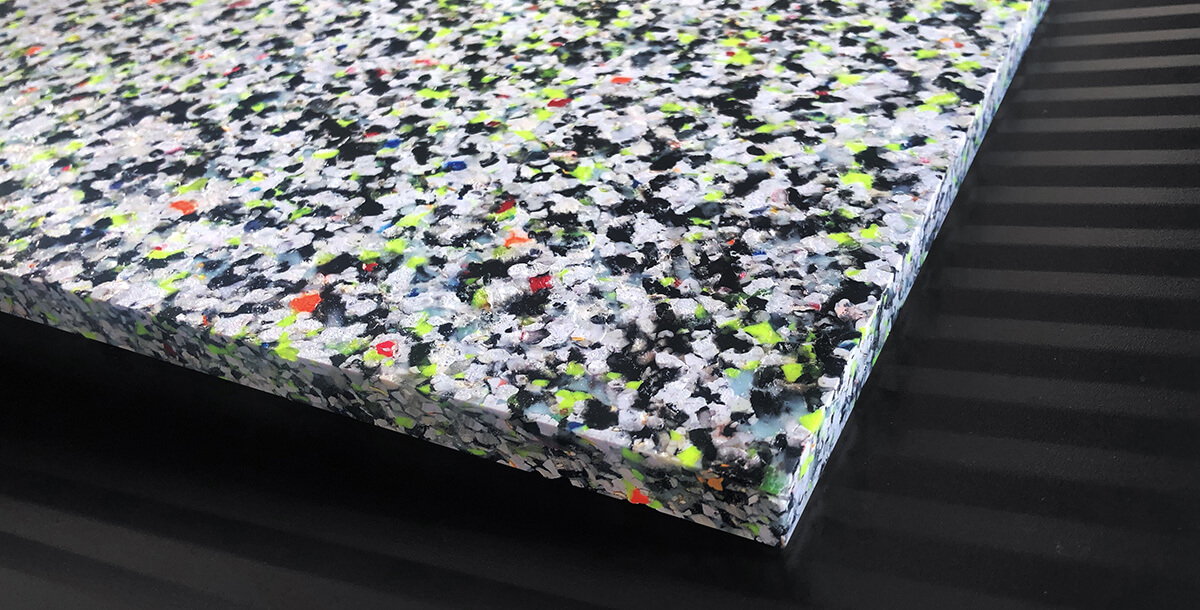

Firstly, we subject polyisocyanurate foam (PIR), a subtype of rigid polyurethane foam, and polyurethane foam (PUR) to a special grinding process, in a ratio of 70-30%. Once the right particle size is obtained, a custom-formulated binder is added to the pellets. After the reactions take place, polyurethane foam sheets can be re-produced.

The main advantage of this process over currently used technologies is that it does can undergo without usinge heat to recycle polyurethane foam, thus resulting in significant energy savings. To enhance the environmentally friendliness of the solution even further, the polyol in the prepolymer used in the process has been replaced by a vegetable-based oil. The catalyst can be sourced from Hungarian manufacturers, thus strengthening economic cooperation among local companies.

Technical assistance and laboratory tests are provided by the Department of Polymer Technology, Faculty of Mechanical Engineering, Budapest University of Technology.