This article is about mobile clean room containers - a flexible solution for clean space capacity that has recently gained notable popularity in the clean room industry. To get an overall picture on why they have caught on, it is key to understand both their advantages and disadvantages.

There are several ways to differentiate clean rooms. The most common way to categorize them is according to their level of purity into different ISO classes from 1 to 8, or according to their building material.

Based on mobility, there are 4 type of clean rooms:

- Traditional clean rooms - made of hard walls, cannot be moved to another location.

- Modular clean rooms - more flexible setup, because they are made of lightweight aluminum building elements that can be assembled quickly and with the precision of prefabricated systems.

- Portable clean rooms - made of materials (for example foil or plexiglass) that are easy to install and transport.

- Mobile clean rooms - are built in a container, can be moved to any location easily, all you need is a suitable power source to work them.

General overview on mobile clean room containers

Compared to traditional clean rooms, mobile clean room containers are more affordable, because costly building materials such as hardwall are not needed. Installation requires significantly less effort, as well. Due to the speed and continuity of production processes, manufacturing companies often simply do not have the time, resources or the necessary labor force to build or extend an existing clean room from scratch. This is when mobile clean room containers may prove to be incredibly beneficial.

In terms of the above mentioned aspects, mobile clean room containers can help companies adapt to rapidly changing requirements. In many cases, it might be a more reasonable decision to invest in a mobile cleanroom container than to build a traditional clean room.

Mobile clean room containers have several advantages and disadvantages compared to traditional or modular clean rooms. In the following, we provide an overview on the most important aspects.

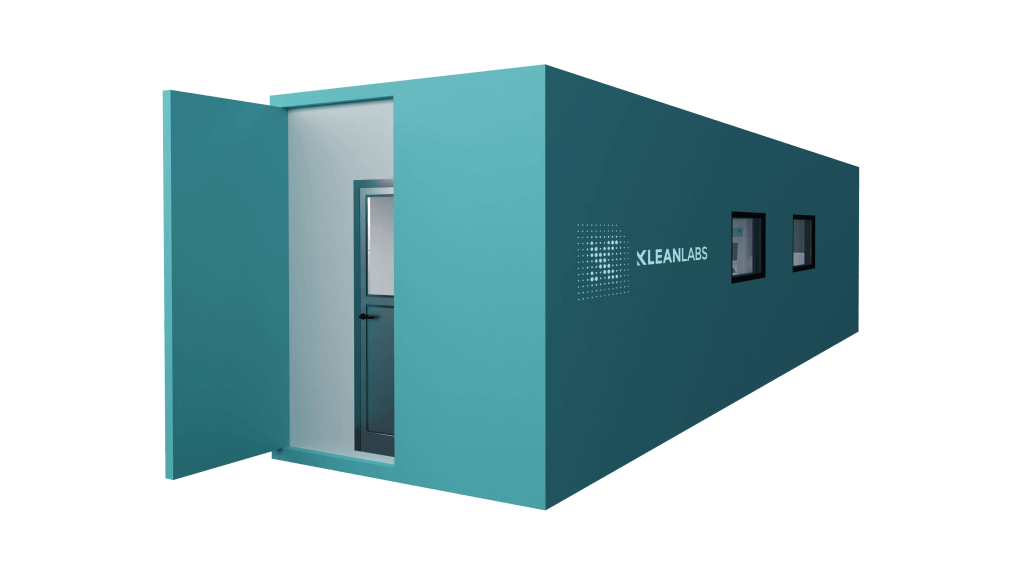

KleanLabs mobile clean room containers are built onto the structure of a standard marine container

Pros of mobile clean room containers

Affordability

Given their transportability, mobile clean room containers are smaller than traditional clean rooms, so less material is required to build them, therefore they tend to be more affordable. The price per square meter of the mobile clean room containers is also lower, because there is no need to create a fixed structure.

Each traditional clean room must be custom designed in terms of layout, air handling system and equipment. In the case of mobile clean room containers, everything is standardized. There is no need to custom design the walls, roofing, ceiling, place of air handling system and other equipment, because the container structure is given.

Building a clean room from scratch is a complicated and time consuming task. The process usually requires several subcontractors, taking a significant amount of time. Permits and inspections are also necessary during the construction process.

What is more, construction of a traditional clean room may result in a production stop, lasting for weeks. Mobile clean room containers function as plug and play units, meaning that they can be used immediately, avoiding any income loss because of a production stop.

Beside all these advantages, it is important to note that price always depends on the specific set of equipment required and standards the clean room must meet. Obviously, clean zones that can provide ISO Class 5 conditions are more expensive than those that can only provide ISO 8 .

Fast assembly & quick availability

Mobile clean room containers are built up of standard components, making their assembly fast and easy. Unlike traditional clean rooms that are assembled on the spot, mobile clean room containers are pre-assembled by the manufacturer, making the installation process faster and easier.

If you opt for a mobile clean room container, you can save significant time and money on preparation and continuous monitoring during the installation process. No to mention that the installation of pre-assembled clean room containers does not produce dirt or dust at the location.

Portability of mobile clean room containers

Mobile clean room containers, as their name indicates, are easy to transport. The standard size of a container is 20 or 40 feet, implying compatibility with various means of transport, such as container ships, container trains or even trucks.

Moreover, containers are designed to be able to be moved in various ways, either from the bottom (eg. by forklift) or from above (eg. by crane). Key features are the weight making them possible to be transported and the heavy-duty build up, guaranteeing that they do not get damaged easily while moving from one place to another.

Resistance to harsh conditions

Mobile clean room containers must be resistant to extreme circumstances so they can perform well even in industrial environments. The containers are made of steel, which is galvanized and painted. (If the surface does not receive appropriate treatment, salty air and vapor may lead to rusting, resulting in structural damages in the container.)

They can resist both chemical - such as

- harsh weather,

- high level of humidity,

- salty air -

and physical impacts.

Although mobile clean room containers’ equipment can be customized to meet specific industry needs, its layout has certain limitations

Cons of mobile clean room containers

Lack of space

Given the standard size of mobile clean room containers, the interior can be relatively cramped. Space can be increased only by doubling standard dimensions, resulting in additional costs.

ISO standards

An important aspect to consider is that mobile clean room containers can be certified to ISO08 and ISO07 according to the ISO14644 classification. If a lower ISO class is needed, clean room containers are likely to be insufficient.

Layout

The floor area of the containers is rectangular-shaped in each case in a ratio of 1: 3 or 5: 1, resulting in limited arrangement options in the container.

Introducing the KleanLabs mobile clean room container

We have only recently put our Kleanlabs mobile clean room container on the market. The container complies with the requirements of biology, military or medical labs. It comes in 3 standard sizes:

- Normal - 20 ft

- Large - 40 ft

- Double - 2 x 40 ft

KleanLabs mobile clean room containers are highly customizable, special needs can be met by equipping the mobile clean room container with an IT network, a sterile washbasin, a camera system or many other options.