While centralized clean room air handling has certainly been a champion of cleanliness, decentralized systems have become more and more popular in practice due to their major cost advantage. Decentralized systems filter and control the air locally with fan filter units (FFUs), meaning that the clean area can be broken up to several smaller clean rooms of different cleanliness classes (meeting different ISO class standards) to save operational costs. The following outlines how such FFU controlled clean spaces work in practice and what you should absolutely consider before opting for either air handling system.

Basics of air handling systems

No wonder that air handling systems usually make up the largest portion of the clean room installation budget since they are the most complex system of the clean room environment. Still, what makes them so essential?

Air handling systems are responsible for complying with the given clean room standard. Should the system not meet the requirements of a certain ISO class, miss to filter particles above a certain size or guarantee the required number of air exchanges per hour, compliance of the entire clean space could be questioned.

Moreover, ensuring an adequate air exchange rate usually results in high operational costs. Thus, smooth operation and regular maintenance of the air handling system both enjoy special attention.

When clean room manufacturers and contractors face the decision of choosing the suitable air handling system, they weigh a number of factors such as

- performance,

- cost,

- reliability,

- sustainability.

It only adds to the importance of the decision that it is rather troublesome to modify the system once it is in operation. Optimization should always precede commissioning.

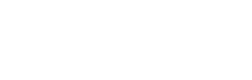

Central HVAC systems always control to the lowest denominator and heat up up the air locally

Central or ducted HVAC system - standard solution

Centralized HVAC (Heating, Ventilation and Air Conditioning) systems are controlled by a central air handling unit (commonly abbreviated as AHU). Air is delivered and removed from the clean space through the ducts and generally circulated back to the central air handling unit. Central or ducted solutions are considered as the conventional approach to supplying air.

What are the benefits of a central HVAC system?

The greatest advantage of a centralized HVAC system is that all relevant metrics can be controlled very precisely such as temperature, humidity and pressure. Consequently, the highest levels of cleanliness can be achieved with a centralized system. Of course, the superior precision of the system is reflected in both installation and maintenance costs.

Expert advice:

If the clean environment consists of zones of different cleanliness classes, it is advised to maintain a pressure differential between the zones, in order to avoid less clean air leaking into a zone of a higher cleanliness class.

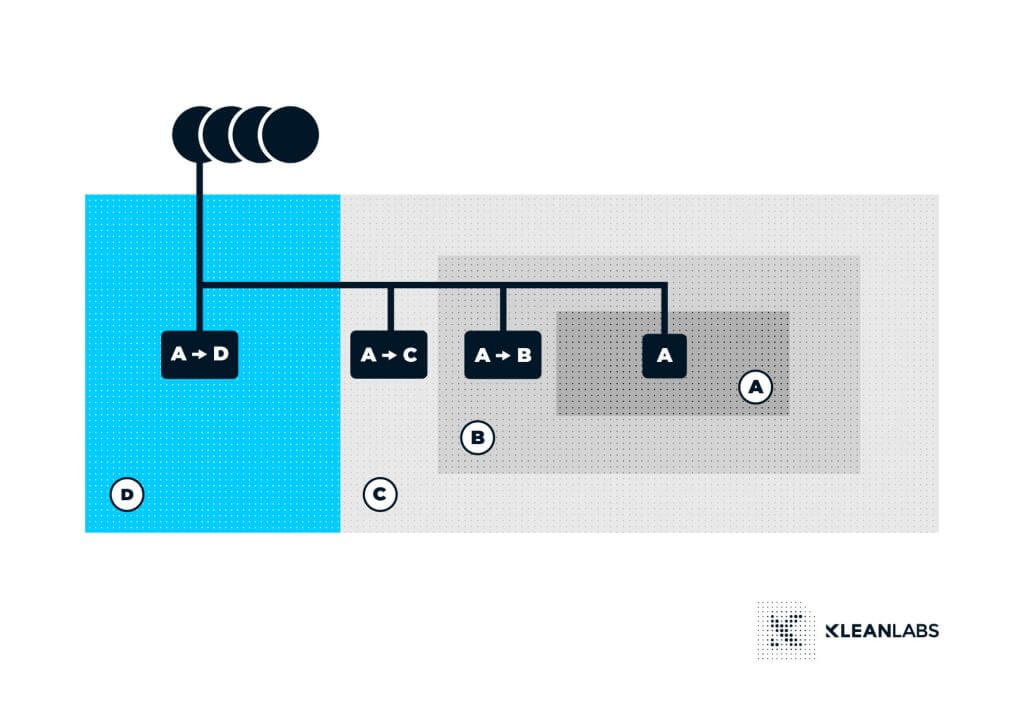

With Fan Filter Units, each section of the clean room is supplied with air of the right temperature

Decentralised air handling with FFUs

Installing individual Fan Filter Units (FFUs, also called integrated blower modules) in your clean environment can eliminate the need for a central air handling unit. These stand-alone units are installed locally in the clean space and can control temperature and humidity sectionally. The clean and filtered air enters the clean room through the ceiling mounted fan filter units equipped with HEPA filters.

FFUs are individually equipped with all essential parts of an air handling system:

a HEPA or ULPA filter,

a fan for ventilation,

a motor.

What are the benefits of Fan Filter Units?

Due to lower installation costs, decentralized solutions have become more and more common in clean room practices. FFUs can be installed in both small and large spaces of as low as ISO 5 class.

How many Fan Filter Units does a clean room need?

Depending on the required air exchange rate and cleanliness class, the number of fan filter units a given clean room can be calculated. Of course, there are several other factors that play a key role such as physical properties of the clean room. Also, the system cannot be changed retrospectively, therefore, clean room experts should be consulted for the precise calculation.

Centralized HVAC systems are the most precise air handling systems

How does the precise calculation look like?

Computational fluid dynamics can help with modelling before the manufacturing begins to estimate air supply and exhaust vents on airflow models. Using this modelling technique, you may be able to decrease the amount of FFUs needed, reducing the initial investment.

Use this rule of thumb for estimation

You can easily estimate how many FFUs you will need with a single metric called ceiling coverage:

| Cleanliness class | Ceiling coverage (%) |

| ISO 8 | 5-15% |

| ISO 7 | 15-20% |

| ISO 6 | 25-40% |

| ISO 5 | 35-70% |

Cost benefits with smaller zones

FFUs have a great operational cost saving potential, as well. By breaking up the clean environment into smaller zones of different cleanliness classes and minimizing the area of the cleanest zone, a significant proportion of expenses can be cut. Fan filter units allow for individual control of these different zones.

What are the drawbacks of smaller zones?

Obviously, this solution adds some complexity to the system, but most times the savings are far worth the additional design effort.

Savings do not work the same way with a central HVAC system

What happens if you insist on breaking up the clean space into smaller zones, but would rather opt for a centralized HVAC system? The central system controls to the lowest denominator and will then locally heat up the air to the required level. Such a solution would result in wasting a lot of energy.

Additional operational benefits of FFUs

From an operational point of view, FFUs can be extremely useful because they increase the operational stability of the system. If a single FFU were to fail, other units could compensate by working at an increased rate. Moreover, fan filter units can be set to two different states: operation mode and setback mode. The latter is convenient when the zone is not in operation but cleanliness should be maintained regardless. Setback mode can still assure compliance during out of shift periods and result in cost saving at the same time.

Key takeaways regarding Fan Filter Units

Given the high complexity of every clean room project, we recommend getting expert consulting before making an investment. It might be very handy to know about the cost benefits of FFUs, but the air handling system will have to be adjusted to the unique circumstances. We are currently working on a major project with FFUs, which will serve as the basis of a detailed and practical case study. We are very much looking forward to reporting on our experiences.